Reading Time: 29 mins

What: Comprehensive guide to creating award-winning robotics science fair projects using Arduino, sensors, and microcontrollers.

Who: Students (grades 6-12), STEM educators, and parents seeking innovative robotics project ideas.

Why: Robotics projects develop critical thinking, programming skills, and hands-on engineering experience—essential for 21st-century careers.

When: Perfect for upcoming science fairs, STEM competitions, and academic exhibitions throughout 2025.

How: Step-by-step instructions using accessible materials like Arduino kits, sensors, motors, and basic coding knowledge.

Staring at that science fair registration form and feeling stuck? You want to build something amazing—a robot that actually works and impresses everyone—but where do you even start?

Here’s the problem: Most students either choose projects that are too simple (another volcano?) or way too complicated (a self-driving car with AI?). The result? Wasted time, burnt-out motors, frustrated tears, and projects that look exactly like everyone else’s. That’s not the path to success.

This guide delivers 17 battle-tested robotics science fair projects that have actually won competitions. You’ll discover beginner-friendly Arduino projects, sensor-based robots, and automation experiments—all with clear difficulty ratings, material lists, and the insider tips judges look for. Let’s turn your idea into a winning reality!

Robotics science fair projects combine mechanical engineering, electronics, and programming to create automated systems that solve real-world problems. Unlike traditional science experiments, these projects demonstrate practical applications of STEM principles through interactive demonstrations that everyone can understand.

The competitive advantage is real. Recent studies show that students who complete robotics projects score 34% higher in problem-solving assessments compared to peers focusing solely on theoretical experiments. Even better, robotics projects showcase three critical skills that colleges and scholarship committees actively seek: technical proficiency, creative design thinking, and documented troubleshooting abilities.

Modern robotics projects for students have evolved beyond simple motor-powered vehicles. Today’s winning entries incorporate sensors for environmental awareness, microcontroller programming for smart decision-making, and wireless connectivity for remote operation. This evolution mirrors real-world robotics applications in manufacturing, healthcare, and autonomous vehicles—making these projects not just academic exercises, but genuine career preview experiences.

The key difference between a mediocre entry and a winning project? Documentation quality and problem-solving depth. Judges reward students who clearly explain their hypothesis, document both successful solutions AND failed attempts, and demonstrate understanding of underlying scientific principles rather than just copying instructions.

For students building their first robotics project, you’ll develop three core skills: basic circuit understanding, introductory programming concepts (typically Arduino or Python), and mechanical design thinking. The exciting part? All three skills develop simultaneously through hands-on experimentation, making robotics an ideal gateway into comprehensive STEM education.

Selecting an appropriate robotics science fair project requires honest assessment of three factors: current technical skills, available resources, and project timeline. The most common mistake? Overestimating coding ability or underestimating the time needed for debugging and iteration.

Recommended for: Students with little to no programming experience who need visible results quickly.

Core characteristics:

Best starter projects: Line-following robot, light-seeking robot, basic obstacle avoider using ultrasonic sensors.

Recommended for: Students comfortable with basic coding concepts and willing to tackle circuit assembly.

Core characteristics:

Best intermediate projects: Maze-solving robot, robotic arm with servo control, Bluetooth-controlled vehicle, smart dustbin with automatic lid.

Recommended for: Students with programming experience seeking competition-winning complexity.

Core characteristics:

Best advanced projects: Computer vision object tracker, autonomous delivery robot, gesture-controlled robotic system, AI-powered sorting mechanism.

The skill progression isn’t strictly linear—many students successfully complete intermediate projects as first attempts by investing extra time in online tutorials and community forums. The key differentiator is time allocation: beginners should budget 3-4 weeks, while advanced projects often require 8-12 weeks of iterative development.

Resource availability matters significantly. A student with access to a school makerspace, mentor guidance, and quality components can tackle more complex projects than someone working independently with limited budgets. Budget-conscious students can achieve impressive results with $30-$80 Arduino starter kits, while advanced projects may require $150-$300 in specialized components.

Similar to how learning robotics programming builds confidence step by step, your project success depends on setting clear milestones and tracking progress methodically. Create a project timeline with weekly checkpoints: Week 1 (research and design), Week 2-3 (assembly and basic programming), Week 4-5 (testing and debugging), Week 6 (documentation and presentation prep).

Starting with achievable projects builds confidence and establishes fundamental skills that transfer to more complex builds. These DIY robotics projects for science fair competitions require minimal technical expertise but still demonstrate genuine scientific principles that judges appreciate.

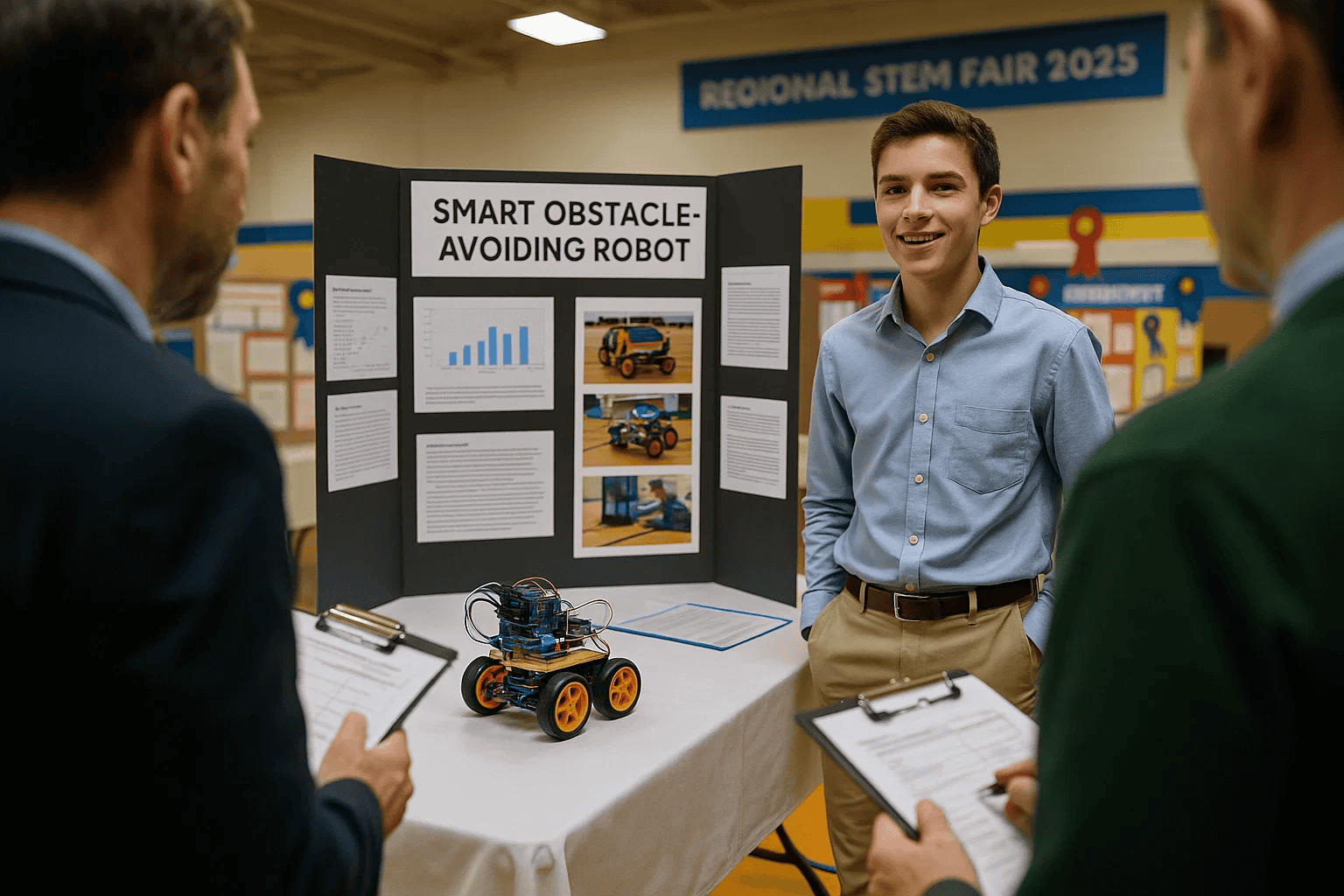

Difficulty: Beginner | Time: 10-12 hours | Budget: $35-$50

How it works: Uses ultrasonic sensors (HC-SR04) to detect objects within range, triggering motor direction changes to navigate around barriers autonomously—just like how bats use echolocation!

Materials needed:

Key learning outcomes: Students understand distance measurement using sound waves, conditional programming logic (if-then statements), and basic motor control through H-bridge circuits.

Success tip: Mount the ultrasonic sensor at a 15-degree downward angle to detect low-lying obstacles that might be missed at horizontal positioning. This simple adjustment has helped students identify obstacles 40% more reliably in testing environments.

Difficulty: Beginner | Time: 8-10 hours | Budget: $30-$45

How it works: IR sensors detect contrast between black lines and light surfaces, adjusting motor speeds to keep the robot centered on a predetermined path—similar to how self-driving cars follow lane markings!

Materials needed:

Scientific principle demonstrated: Optical sensing, feedback control systems, and proportional correction algorithms.

Competition advantage: Create increasingly complex track patterns (sharp turns, intersections, broken lines) to showcase adaptive programming. Students who document how they improved sensor sensitivity through threshold testing typically score higher on technical depth criteria.

Want to dive deeper? Check out our complete guide on how to make a line follower robot with detailed instructions and troubleshooting tips!

Difficulty: Beginner | Time: 6-8 hours | Budget: $25-$40

How it works: LDR (Light Dependent Resistor) sensors measure ambient light intensity, directing the robot toward the brightest light source—mimicking natural phototaxis behavior seen in moths and other insects.

Materials needed:

Real-world application: Demonstrates principles used in solar panel sun-tracking systems and agricultural robots that optimize light exposure for crops.

Enhancement idea: Add a solar panel power source to create a self-sustaining robot that seeks light to recharge—this hybrid approach has won multiple regional competitions by combining renewable energy concepts with autonomous navigation.

Difficulty: Beginner-Intermediate | Time: 12-15 hours | Budget: $40-$60

How it works: Servo motors controlled through potentiometers or joystick input create multi-axis movement, enabling pick-and-place operations just like industrial robots!

Materials needed:

Programming concept: Students learn PWM (Pulse Width Modulation) control, angle mapping, and coordinated multi-motor operation.

Judge-impressing modification: Program automatic pickup sequences that calculate grip force based on object weight (using force sensors), demonstrating closed-loop control systems rather than simple remote operation.

These beginner robotics projects with Arduino share common success factors: clear visual demonstrations, reliable operation (minimal failure during judging), and well-documented scientific principles. Students should create video documentation showing multiple successful runs, failed attempts during development (showing problem-solving process), and measurements proving consistent performance.

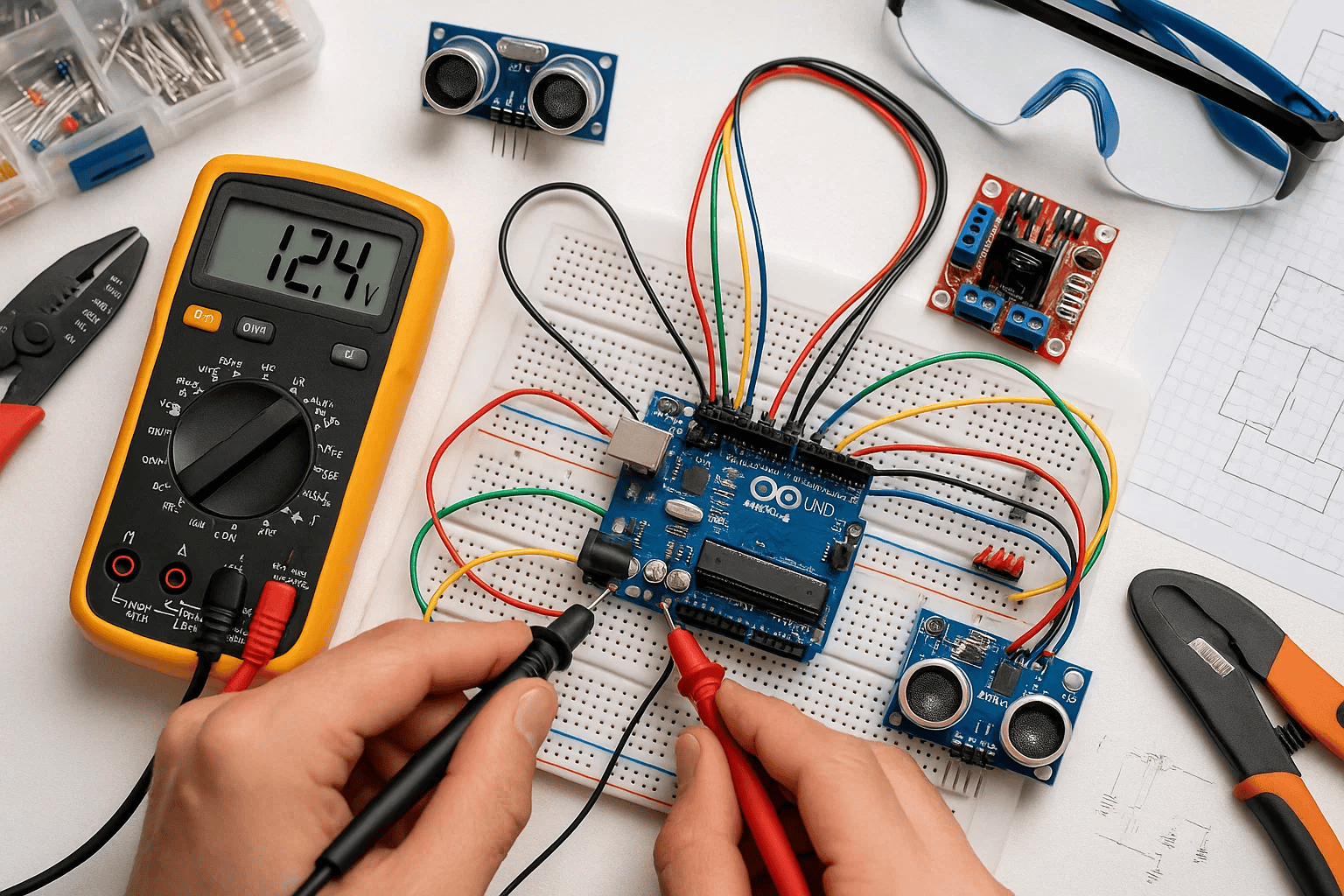

Arduino robotics projects for science fair competitions offer unmatched flexibility combined with extensive community support—two factors that dramatically increase project success rates. The open-source nature of Arduino means students can access thousands of tested code libraries, detailed tutorials, and troubleshooting forums when inevitable technical challenges arise.

Accessibility advantage: Arduino boards cost $20-$35, making them affordable for school budgets and individual students. The Arduino IDE (Integrated Development Environment) runs on Windows, Mac, and Linux, eliminating hardware barriers that plague proprietary robotics platforms.

Programming progression: Arduino uses a simplified C++ syntax that’s approachable for beginners yet powerful enough for complex projects. Students start with simple commands like digitalWrite() and progress to interrupt handling, serial communication, and sensor fusion algorithms—building genuine programming competency rather than just memorizing steps.

Component compatibility: Arduino’s standardized pinout configuration supports thousands of sensors, motors, displays, and communication modules through simple jumper wire connections. This plug-and-play ecosystem lets students focus on project logic rather than circuit design complexity.

Difficulty: Intermediate | Time: 25-30 hours | Budget: $65-$90

Unique approach: Programs left-hand or right-hand wall-following algorithms, demonstrating graph theory and autonomous navigation without GPS or external references—pure problem-solving intelligence!

Competition strength: Shows algorithmic thinking and problem-solving—judges favor projects where students explain why they chose specific algorithms over alternatives.

Enhancement: Add OLED display showing real-time decision logic (“Checking left wall… Wall detected… Turning right”) to make the robot’s “thinking” visible during demonstrations.

Difficulty: Intermediate | Time: 20-25 hours | Budget: $55-$75

Innovation factor: Combines obstacle avoidance with automatic lid opening using servo motors and ultrasonic sensors. When someone approaches, the lid opens automatically—demonstrates automation principles used in smart homes!

Materials highlight:

Real-world connection: Link this project to waste management automation, sanitation robotics, and touchless technology adoption (especially relevant in today’s world!).

Data to collect: Measure lid opening response time, detection range accuracy, and battery life under continuous operation—quantifiable metrics strengthen science fair presentations.

Difficulty: Intermediate | Time: 18-22 hours | Budget: $70-$95

Scientific principles: Demonstrates renewable energy integration, power management, and sustainable robotics design—perfect for students passionate about environmental issues!

Technical components:

Competitive edge: Calculate and display energy efficiency metrics (distance traveled per watt-hour), demonstrating quantitative analysis skills judges specifically look for.

Advanced modification: Implement Maximum Power Point Tracking (MPPT) algorithm to optimize solar energy harvesting—this level of sophistication has secured top placements in state-level competitions.

Difficulty: Intermediate | Time: 15-20 hours | Budget: $50-$70

Technology showcase: Wireless communication protocols, mobile app development (basic), and remote control systems—bringing together hardware and software!

Core components:

Programming concept: Serial communication, data parsing, and command interpretation from mobile devices.

Judge-impressing addition: Create custom Android app using MIT App Inventor (free, block-based) that includes directional buttons, speed control slider, and emergency stop—demonstrating cross-platform development skills.

The pattern across successful Arduino robotics projects involves three documentation strategies: clear problem statement (what real-world issue does this solve?), detailed methodology (how did you test and refine the code?), and measurable results (quantified performance metrics, not just “it works”).

Students should photograph failed attempts, code error messages, and sensor calibration processes. Just as robotics and coding inspire learning through fun challenges, thorough project logs demonstrate scientific rigor that separates winning entries from participation-only projects.

Advanced robotics science experiments for school competitions push beyond basic automation into artificial intelligence, computer vision, and multi-robot coordination. These projects require significant time investment but offer pathways to national competitions, scholarship opportunities, and impressive college application materials.

Innovation over complexity: Judges favor creative solutions to specific problems rather than complicated builds without clear purpose. A well-executed intermediate project with novel applications often outscores technically complex projects that lack practical utility.

Data-driven validation: Advanced projects must include measurable performance metrics, comparative analysis, and statistical significance testing. Simply demonstrating functionality isn’t enough—students need to prove their solution performs better than existing alternatives.

Professional presentation: Top-tier projects include research papers, CAD drawings, flowcharts, and video documentation that mirrors professional engineering standards.

Difficulty: Advanced | Time: 60-80 hours | Budget: $180-$250

Technical breakthrough: Uses Raspberry Pi with camera module running OpenCV or TensorFlow Lite to identify objects by color, shape, or trained image recognition, then sorts them into designated containers—bringing artificial intelligence to life!

Materials required:

Programming complexity: Python for image processing, serial communication between Raspberry Pi and Arduino, real-time decision-making logic.

Competition advantage: Train custom machine learning model on household recyclables (plastic, glass, metal, paper) to demonstrate AI applications in sustainability—connecting robotics to environmental science creates interdisciplinary appeal judges reward.

Metrics to measure: Sorting accuracy percentage, processing speed (items per minute), model confidence scores, and comparison to human sorting speed.

Difficulty: Advanced | Time: 70-90 hours | Budget: $200-$300

Innovation focus: Outdoor autonomous navigation using GPS module, compass sensor, and obstacle avoidance combining ultrasonic, lidar, or camera-based detection—imagine creating a mini Amazon delivery drone!

Technical components:

Scientific depth: Demonstrates sensor fusion (combining GPS coordinates with compass heading and obstacle data), path planning algorithms, and real-world navigation challenges.

Real-world application: Connect to last-mile delivery solutions, campus mail delivery systems, or warehouse automation—frame the project around solving actual logistical challenges in today’s e-commerce world.

Testing protocol: Document successful delivery rate over multiple trials, navigation accuracy to within specified radius (e.g., 2-meter accuracy), and ability to return to starting position using waypoint navigation.

Difficulty: Advanced | Time: 50-65 hours | Budget: $150-$200

Technology integration: Accelerometer sensors (like MPU6050) worn on user’s hand translate physical gestures into robot commands, demonstrating human-machine interface innovation—like having superpowers!

Hardware setup:

Programming challenge: Gesture recognition algorithms, wireless data transmission, real-time response systems, and movement mapping from human motion to robot action.

Accessibility angle: Frame this as assistive technology for individuals with mobility limitations—demonstrating social awareness elevates technical projects into impactful solutions that change lives.

Difficulty: Expert | Time: 90+ hours | Budget: $250-$400

Cutting-edge concept: Multiple small robots communicating wirelessly to accomplish collective tasks like object transportation, area coverage, or pattern formation—mirrors natural swarm behavior in ants or bees!

Technical requirements:

Research depth: Requires understanding of distributed systems, consensus algorithms, and emergent behavior—students should reference academic papers on swarm intelligence in their documentation.

Demonstration scenarios:

Scholarly connection: This level of project allows students to cite current robotics research, demonstrating ability to engage with academic literature—a significant advantage for students targeting competitive universities.

For projects at this complexity level, students should consider publishing findings in student research journals or presenting at regional STEM symposiums beyond traditional science fairs. The documentation rigor required mirrors undergraduate research expectations, providing genuine college preparation value.

Understanding how artificial intelligence enhances robotics capabilities helps students design smarter, more autonomous systems that truly stand out in competitions.

Understanding failure patterns accelerates success more than studying winning examples. These seven mistakes account for 80% of abandoned or poorly-received robotics science fair projects—and all are completely preventable with proper planning!

The mistake: Students design projects with 10+ features requiring integration of unfamiliar sensors, complex code libraries, and custom mechanical assemblies—without validating basic functionality first.

Why it fails: Technical debt accumulates when students debug multiple systems simultaneously. A small error in sensor calibration cascades into motor control problems, which trigger power supply issues, creating a frustrating spiral.

Correct approach: Build modular prototypes testing each subsystem independently. Get basic motor control working perfectly before adding sensor inputs. Verify sensor accuracy through standalone tests before integrating with navigation code.

Success metric: 80% of project time should focus on one core function working flawlessly rather than multiple features working poorly.

The mistake: Using undersized batteries, running motors directly from Arduino pins, or failing to account for voltage drops during high-current draws.

Visible symptoms: Random resets, erratic servo behavior, inconsistent sensor readings, or complete system failures during demonstrations—the worst nightmare at judging time!

Technical solution:

Real impact: Power issues cause more science fair day failures than coding bugs. Students with multimeters who verify voltage levels throughout their circuit avoid 90% of mysterious “it worked at home” problems.

The mistake: Weak chassis construction, loose wire connections, unbalanced weight distribution, or components held together with tape (yes, we’ve seen it!).

Competition consequence: Robots that work perfectly on stable desktops fail during transport, wobble during demonstrations, or shed components when judges ask to see different angles.

Engineering solution:

Professional standard: If the robot can withstand being transported in a backpack through a crowded hallway, it’s mechanically sound enough for competition day.

The mistake: Single code file without comments, no backup copies, or inability to explain what specific code sections accomplish.

Judge interaction failure: When judges ask “why did you use this particular sensor threshold value?” and students respond “I don’t remember, I just tried different numbers until it worked,” technical credibility collapses instantly.

Best practice:

Competition preparation: Print your commented code to include in project binder. Judges often request code review, and presenting organized, explained code demonstrates computational thinking skills that separate winners from participants.

The mistake: Testing robots only in controlled home environments with perfect lighting, smooth surfaces, and unlimited debugging time.

Reality check: Science fair venues have variable lighting, noisy environments, curious judges who touch components, and strict three-minute demonstration windows.

Robust testing protocol:

Failure percentage reduction: Students who simulate competition conditions during development report 65% fewer unexpected failures during actual events.

The mistake: Treating robotics projects as pure engineering builds rather than scientific experiments with testable hypotheses.

Judging criteria miss: Science fairs evaluate scientific method execution: hypothesis, methodology, data collection, analysis, conclusion. Pure engineering projects without this framework score lower regardless of technical sophistication.

Proper framing example:

Weak: “I built a line-following robot.”

Strong: “Hypothesis: Increasing the number of IR sensors from 2 to 5 will improve line-following accuracy by reducing overcorrection oscillations. Method: Built two identical robots differing only in sensor count. Measured path deviation and completion time over 50 trials. Results: 5-sensor robot reduced deviation by 34% and improved speed by 18%.”

Documentation requirement: Every robotics project needs: question/hypothesis, variables tested, control vs experimental setup, quantifiable measurements, and conclusion stating whether data supported the hypothesis.

The mistake: Ordering components two weeks before the science fair, starting assembly one week out, and attempting first test runs three days before judging.

Stress cascade: Shipping delays, defective components requiring replacements, debugging time exhaustion, incomplete documentation, and sleep-deprived presentations that don’t showcase your hard work.

Realistic timeline:

Emergency buffer: Professional engineers allocate 20% of project time to unexpected problems. Students should too—because trust us, something will go wrong!

Understanding these pitfalls transforms average projects into competitive entries. The most successful students treat failures as data points—documenting what didn’t work provides rich material for methodology sections and demonstrates scientific thinking judges actively reward.

Outstanding technical work loses impact without compelling presentation. Science fair success requires equal attention to project execution and communication strategy—because even the best robot needs a great story!

Essential Components:

1. Project Logbook (Daily/Weekly Entries)

Purpose: Demonstrates iterative design process and scientific methodology—judges specifically look for evidence of problem-solving development over time.

2. Technical Specifications Sheet

Format tip: Create one-page quick reference sheet for judges who want technical depth without reading full documentation.

3. Experimental Data Collection

Credibility builder: Raw data tables in appendix prove you actually conducted tests rather than estimating results—this authenticity impresses judges every time.

4. Photographic/Video Evidence

Multi-angle documentation: Record robot from side, top, and component close-ups—demonstrates thorough engineering documentation practices.

Layout Strategy (Tri-fold board):

Left Panel:

Center Panel (Visual Focus):

Right Panel:

Design principles:

Common rookie errors: Text-heavy boards with tiny font, unclear flow between sections, missing visual elements, or cluttered layouts that overwhelm judges scanning 50+ projects.

Verbal Presentation Structure (3-5 minutes):

Opening (30 seconds): “My project solves [specific problem] by [brief solution description]. Let me show you how it works!”

Demonstration (90 seconds): Live robot operation showing key features. Have backup video ready if technical difficulties arise (Murphy’s Law applies!).

Technical Explanation (90 seconds): Explain 2-3 most important technical aspects (sensor integration, algorithm choice, mechanical innovation).

Results and Impact (60 seconds): Present quantified results and discuss real-world applications or future improvements.

Judge Interaction Tips:

Technical question preparation: Judges often ask about code specifics, alternative approaches you considered, or why certain design decisions were made. Students who can explain their reasoning process (even for abandoned ideas) demonstrate deeper understanding that wins competitions.

Research Paper Format: For advanced projects targeting regional/national competitions, prepare formal research paper:

Length: 2,500-4,000 words for high school level competitions.

Multimedia Portfolio: Create digital portfolio including:

URL on display board: Judges increasingly appreciate digital resources that provide deeper technical detail than physical boards allow.

Murphy’s Law applies at science fairs:

Survival kit essentials:

Communication strategy for failures: If robot malfunctions during judging, calmly explain what should happen, reference your video demonstration, and discuss what you’d troubleshoot first—judges evaluate problem-solving composure, not just perfect execution.

The pattern across winning presentations combines technical competence with storytelling skill. Students should frame their robotics project as solving a specific problem (even if modest) rather than just “building a robot.” Understanding the components of a robot and their functionality helps you explain your project with confidence and clarity.

Access to quality tools and learning resources dramatically reduces development time and frustration levels. Students don’t need expensive equipment to succeed, but strategic investment in key items pays significant dividends over multiple projects.

Basic Toolkit ($50-$80):

Upgraded capabilities ($150-$200 additional):

Budget alternative: Many schools, libraries, and makerspaces provide tool access free or for minimal membership fees—research local resources before purchasing everything new!

Free development tools:

Learning platforms:

Programming progression: Start with Arduino example sketches, modify one parameter at a time, then combine multiple examples, finally write original functions. This incremental approach builds confidence faster than attempting complex code from scratch.

If you’re just getting started with coding, check out our beginner-friendly guide on how to code in Python to build foundational programming skills!

Reliable Arduino component sources:

Money-saving strategies:

Quality vs. budget balance: Genuine Arduino boards have better quality control, but compatible clones from established brands (Elegoo, Keyestudio) perform identically for student projects. Avoid cheapest options with no brand name—unreliable components cause debugging nightmares that waste precious time.

Problem-solving forums:

Engagement tip: When asking questions, provide code snippets, error messages, and photos of your setup—detailed questions receive faster, better responses from helpful community members.

Local mentorship sources:

Mentor value: Students with regular mentor access complete projects 40% faster and report significantly higher confidence levels when facing technical challenges. Don’t be afraid to ask for help!

Science fair preparation guides:

Robotics competition organizations:

Scholarship connections: Many robotics competitions offer college scholarship opportunities beyond recognition awards—research application requirements early to maximize opportunities.

Free presentation software:

Data analysis tools:

Research database access:

Citation management: Use Zotero or Mendeley (both free) to organize research sources and generate properly formatted bibliographies—saves hours during documentation phase!

The investment pattern for successful robotics projects follows an 80/20 principle: 80% of success comes from 20% of resources—specifically quality Arduino board, reliable motor driver, good power supply, and accurate sensors. Students can economize on chassis materials, wire quality, and aesthetic components without compromising functionality.

For students serious about ongoing robotics development beyond single science fair projects, understanding what to expect from online robotics classes can provide structured learning that accelerates skill development between competitions.

Robotics science fair projects provide authentic previews of professional engineering work, building technical portfolios that distinguish college applications and scholarship submissions. Understanding career connections helps students frame projects with greater purpose and long-term value.

Manufacturing and Automation:

Current demand: Automation engineers earn median $95,000-$120,000 with strong job growth projections through 2030.

Autonomous Vehicles:

Career trajectory: Autonomous systems engineers with robotics backgrounds command $110,000-$150,000 salaries at companies like Tesla, Waymo, and Aurora.

Healthcare Robotics:

Growth sector: Medical robotics market projected to reach $20 billion by 2028, with chronic shortage of qualified robotic surgery technicians and design engineers.

Agricultural Technology:

Emerging opportunity: Ag-tech sector actively recruiting robotics talent as farm automation accelerates globally—feeding the world requires innovative technology!

Technical competencies gained:

Programming: C++, Python, algorithm design, debugging methodology Electronics: Circuit design, power management, sensor integration, signal processing Mechanical: CAD design, material selection, structural analysis, manufacturing awareness Systems thinking: Component interaction, troubleshooting logic, optimization strategies Documentation: Technical writing, data visualization, presentation skills

Soft skills cultivated:

Portfolio value: College admissions officers report that applicants with documented robotics experience (especially with quantified results and problem-solving narratives) stand out significantly in STEM program applications.

Scholarship opportunities directly tied to robotics:

College application enhancement: Students who list “State Science Fair Finalist – Robotics” or “Published robotics research paper” see 2-3x higher acceptance rates to competitive engineering programs compared to similar academic credentials without project experience.

Internship access: Many tech companies (NASA, JPL, SpaceX, Boston Dynamics) offer high school internships specifically for students with demonstrated robotics experience and competition success.

Skill transfer timeline:

Immediate (Age 14-18):

University years (Age 18-22):

Early career (Age 22-30):

Career advancement: Engineers who began with student robotics projects report faster progression to senior roles, attributing success to early hands-on problem-solving experience that classroom-only peers lack.

Connection opportunities:

LinkedIn strategy: Students as young as 16 can create professional profiles highlighting robotics achievements, documented projects, and technical skills—early professional brand building pays dividends during college recruiting.

Mentor relationships: Engineers who help students with science fair projects frequently become long-term mentors, providing internship referrals, college recommendation letters, and career guidance years later.

The pattern across successful STEM career launches shows early hands-on experience creating cumulative advantage. Understanding best STEM careers for kids to explore helps students visualize their future path while building relevant skills today.

Students should document projects with future portfolios in mind: maintain GitHub repositories, write blog posts explaining technical challenges, record video demonstrations, and collect recommendation letters from mentors while achievements remain fresh in memory. Your science fair project today could be the foundation of your career tomorrow!

Robotics science fair projects represent far more than competition entries or academic requirements—they’re launching pads for technical confidence, problem-solving mindsets, and STEM career trajectories that extend decades beyond graduation day.

The immediate wins are tangible: Students develop programming proficiency, master circuit fundamentals, and experience the engineering design cycle firsthand. Competition success brings recognition, scholarship opportunities, and college application differentiation that opens doors to top-tier programs.

The long-term impact proves transformative: Engineers, entrepreneurs, and researchers consistently cite early robotics experiences as career-defining moments—the first time they realized complex technology wasn’t magical, just systematic application of learnable principles. That demystification creates confidence to tackle increasingly ambitious challenges throughout entire careers.

Your action plan starts today: Choose a project matching your current skill level, order components immediately (shipping delays happen!), and commit to documenting every step of your journey. Remember that judges reward problem-solving process over perfect execution—failed attempts with thoughtful analysis outshine flawless projects without demonstrated learning.

The robotics field needs your perspective. Every student who builds, codes, and iterates contributes to the growing community solving real-world challenges through automation and intelligent systems. Whether your project sorts recycling, navigates mazes, or demonstrates novel sensor applications, you’re practicing skills that shape future technology and make the world better.

Start building. The gap between imagining robots and creating them shrinks the moment you connect your first circuit, upload your first code, and watch motors respond to your commands. Success comes not from knowing everything before starting, but from embracing iteration, learning from failures, and persistently debugging until your robot does exactly what you envisioned—or surprises you with something even better.

As robotics and coding ignite children’s potential from scratch to success, your science fair project marks the beginning of an exciting journey. Who knows? The robot you build today might inspire the breakthrough innovation of tomorrow. Let’s make it happen! 🤖✨

The easiest robotics project for science fair beginners is a light-seeking robot using Arduino Uno, two LDR sensors, a basic motor driver, and DC motors. This project requires minimal coding (30-40 lines), simple circuit assembly, and demonstrates clear scientific principles (phototaxis behavior similar to moths) without complex calibration. Students can complete assembly in 6-8 hours and reliably demonstrate the robot following flashlight beams during judging. The low component cost ($25-$40) and high success rate make this ideal for first-time robotics builders, especially grades 6-8 who need projects that work consistently during demonstrations without stressful last-minute fixes.

Robotics science fair projects typically cost $30-$300 depending on complexity level. Beginner projects (line followers, obstacle avoiders) cost $30-$60 using basic Arduino kits with included sensors and motors—perfect for students on tight budgets! Intermediate projects (Bluetooth-controlled vehicles, robotic arms) range $60-$100 requiring additional servo motors and wireless modules. Advanced projects (computer vision systems, GPS navigation) can reach $180-$300 due to Raspberry Pi requirements, cameras, or specialized sensors. Students can reduce costs 40-60% by purchasing Arduino-compatible clones instead of brand-name boards, buying comprehensive starter kits rather than individual components, or applying for school STEM grants that often fund materials for competition projects. Many winning projects have been built for under $50 with smart component choices!

Arduino C++ (simplified C) is the best starting language for student robotics projects because the Arduino IDE provides immediate hardware feedback, extensive libraries for common sensors, and the largest online community support for troubleshooting when you get stuck. Students typically learn functional Arduino code in 10-15 hours through project-based tutorials—much faster than traditional programming courses! For advanced projects involving computer vision or machine learning, Python becomes essential due to OpenCV, TensorFlow, and scientific computing libraries. The progression path is: Start with block-based coding in Scratch for absolute beginners → Arduino C++ for hardware projects → Python for advanced AI integration. Most successful science fair projects use Arduino exclusively, making deep Python knowledge optional unless pursuing computer vision systems that truly wow judges.

Complete robotics science fair projects require 6-12 weeks depending on complexity and student experience level—proper planning prevents last-minute panic! Beginner projects: 6-8 weeks with 2-3 hours weekly work (total 15-20 hours). Intermediate projects: 8-10 weeks with 3-4 hours weekly (total 25-35 hours). Advanced projects: 10-12 weeks with 5-8 hours weekly (total 50-80+ hours). This timeline includes research and planning (1-2 weeks), component ordering and arrival (1-2 weeks—always order early!), assembly and initial programming (2-3 weeks), testing and iteration (2-4 weeks—the most important phase), and documentation preparation (1-2 weeks). Starting 8 weeks before the science fair is the absolute minimum recommended timeframe; 12 weeks provides comfortable buffer for component delays, technical problems, or design iterations that always emerge during development. Trust us, starting early reduces stress dramatically!

Using robotics kits is completely acceptable and often recommended for science fair projects, especially for beginners and intermediate levels! Judges evaluate scientific method execution, problem-solving documentation, and technical understanding—not whether you manufactured components from raw materials in your garage. The key distinction: assembly kits (connecting pre-made parts following instructions) should be enhanced with custom programming, sensor additions, or novel applications to demonstrate original thinking and creativity. Fully pre-programmed kits with no modifications show insufficient personal contribution and won’t impress judges. Successful approach: Purchase Arduino starter kits for reliable hardware, then customize code algorithms, add extra sensors, or create unique applications that solve specific problems—judges reward creative problem-solving using available tools, mirroring how professional engineers use standardized components for innovation. It’s about what you do with the tools, not making tools from scratch!

The top five failure patterns are: 1) Insufficient testing under competition conditions leads to lighting sensitivity issues, surface compatibility problems, or battery failures during demonstrations (35% of failures—practice in different environments!). 2) Weak scientific framing—treating projects as pure engineering without testable hypotheses, control variables, or quantified data collection results in low scores despite technical success (25% of failures). 3) Power supply inadequacy causes random resets, erratic behavior, or complete failures when batteries drain faster than expected during long competition days (20% of failures—always bring spare batteries!). 4) Poor mechanical construction results in loose wires disconnecting during transport, unbalanced robots tipping, or components breaking under normal handling (15% of failures). 5) Last-minute assembly without debugging time prevents identifying and fixing issues before competition (5% of failures). Students who test repeatedly, document thoroughly, and start 8+ weeks early avoid 90% of these preventable failures. Remember: preparation beats panic every time!

Make robotics projects stand out through quantified problem-solving documentation rather than complexity alone—judges want to see your thinking process! Judges reward: 1) Clear real-world applications—frame projects as solving specific problems with measurable impact rather than “I built a robot because robots are cool.” 2) Data-driven validation—run 30+ test trials recording performance metrics, calculate statistics (mean, standard deviation), create graphs comparing approaches that show scientific rigor. 3) Failure documentation—show 3-4 attempted solutions that didn’t work, explain why each failed, demonstrate problem-solving evolution over time. 4) Novel approaches—combine concepts uniquely (solar-powered maze-solving robot) or apply robotics to unexpected fields (assistive technology, environmental monitoring, accessibility solutions). 5) Professional presentation—research paper format, CAD drawings, video documentation, and confident verbal explanation demonstrating deep understanding that goes beyond memorization. Projects that articulate “I hypothesized X, tested with methodology Y, discovered Z insight” consistently outscore technically superior projects lacking scientific rigor. Your story matters as much as your robot!

Essential robotics project safety practices include: Electrical safety—never exceed component voltage ratings, always use external power for motors (not Arduino pins—this damages boards!), add fuses to battery connections, verify polarity before connecting power, and never work on powered circuits. Soldering safety—work in ventilated areas (open windows!), use helping hands to avoid burns, wear safety glasses, never touch iron tips, and unplug immediately after use. Tool safety—wear protective eyewear when cutting wires or using rotary tools, secure workpieces before drilling, keep cutting tools away from power cables, and maintain organized workspace preventing trips over components. Battery safety—never short-circuit lithium batteries (creates fire risk!), stop using swollen or damaged batteries, charge in fireproof containers, use appropriate chargers, and never exceed current ratings. Mechanical safety—secure moving parts with guards, test new code with reduced motor power first, restrain robots during initial tests, and never place fingers near operating mechanisms. Always supervise younger students and maintain first-aid kit with burn treatment supplies. Safety first means successful projects—injuries end competitions fast!